|

The

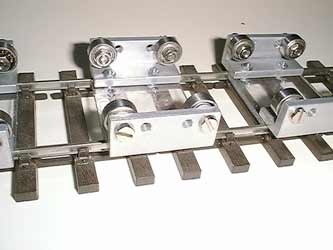

Rolling Road provides a convenient means of running-in,

fault-finding or dynamic testing of locomotives.

The

unit consists of a number of modular components,

which are placed on a length of straight track

and positioned beneath the locomotive axles. The

modules are split centrally, each half being isolated

from the other to enable electric locomotives

to be powered from the track. The unit is suitable

for locomotives of steam, diesel or electric outline.

The

modular system means that individual modules may

be purchased separately, to suit the wheel arrangement

of any particular loco. They can be added to as

and when larger locos are acquired, having a greater

number of driving axles.

The

modules are priced individually, or as a set (typically

a 4-6-2 tender loco).

The

Modules are desribed as follows:

Type

D , for driving wheels. Each block has

4 ball races to support the driving axle.

Type

B (medium) - supports a 4-wheel bogie.

Type

P (short) - supports a single-axle pony

truck

Type

T (long) - for tenders. This will accommodate

the longest (British) tender.

|